Automate Your Titrations: Self-Zeroing Burettes for Unmatched Accuracy

Raising the Bar: Titration with Modern Burettes

Titration endures as a critical method in analytical chemistry, environmental analysis, industrial applications, and institutional quality control. Its value—quantitative precision—means every laboratory professional relies on equipment that offers reproducibility, safety, and long-term chemical compatibility. Today’s best practices emphasize using self-zeroing and automatic burets designed from robust, chemically resistant materials like borosilicate glass 3.3, with rigorous adherence to standards such as ASTM E287 and ISO 385.

Anatomy of Self-Zeroing and Automatic Burettes

Advanced Build and Features

-

Material Choice: Borosilicate glass burets (including special amber for UV radiation protection) and acrylic burets are industry standards for durability, thermal shock resistance, and chemical compatibility, especially for broad pH ranges or dilute mineral acids. Borosilicate glass offers the best combination of purity and resistance, while acrylic is considered for visibility and economics.

-

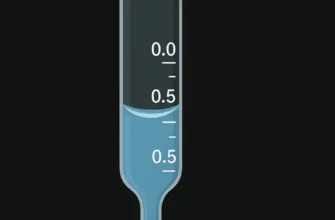

Graduation and Readability: Clear and permanent blue ring graduations, chemical-resistant blue printing, and the Schellbach Stripe or Schellbach stripes (a colored band for enhanced meniscus reading) extend accuracy and ease of use.

-

Dimensions: Details like Burette Capacity, Burette Height, Reservoir Capacity, Joint Size (e.g., 34/35), Base Diameter, and Catalog Number or Catalog No. should be referenced for each purchase, ensuring compatibility with titration work stations or IV Pole Infusion Sacks.

-

Stopcock Excellence: Leak-proof plug and PTFE key stopcocks (also called TFE or fluoropolymer resin stopcocks), 3-way stopcock options, and micro screw regulators provide reliable drop speed and precise volumetric analysis. Burette covers and dust covers prevent outside contamination and ensure chemical compatibility.

-

Reservoir & Tubing: Closed system burettes often integrate with low density polyethylene (LDPE) squeeze bottle assemblies and PVC tubing (commonly 36″ length) for safe, sealed titrant handling, minimizing loss and contamination.

Automation and Compliance

-

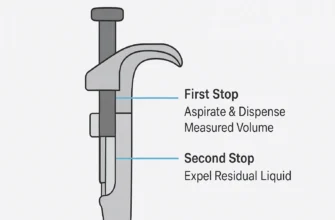

Automatic Zero Facility: Automatic self-zeroing burets enable rapid, air-free zero setting—usually with a gentle squeeze on the LDPE reservoir—removing parallax and operator error. Advanced models such as Burkle splinter-proof burettes offer self-zeroing and dosing armature for high-throughput labs.

-

Calibration and Standards: Adherence to ASTM E287, ISO 385, and ISO 6706 ensures accuracy. NIST-Traceable Calibration, Class A and Class B options, and graduations in accordance with Category B are vital when traceable results are needed for quality control workflows.

-

Classes: Class A burettes yield maximum accuracy (narrowest tolerances), vital for volumetric analysis, RNA/DNA extraction, and pharmaceutical titrations. Class B (wider tolerance) is suitable for field analysis or water treatment plant work where some flexibility is permitted.

Chemical and Application Flexibility

-

Chemical Resistance: Borosilicate glass and PTFE stopkocks handle titrants across the pH range of 1–14; caution is required with hydrofluoric acid or ammonium hydroxide, favoring PTFE or plastic sheathing for specific cases. For strong UV or light-sensitive chemicals, amber glass and plastic-sheathed options protect sample integrity.

-

Compatibility: Automatic burettes can be set up as industrial titration platforms, part of laboratory professionals’ BIO Business Solutions or VWR International supply chains, or for more advanced workflows paired with laboratory PTFE magnetic mixer stirrer bars, magnetic stirrer hot plates, or automated dosing.

-

Accessories and Sustainability: Burette brushes for cleaning, spare jets, joint clips, custom foam packaging, chemical-resistant labeling, and recycling options support sustainability platforms in regulated labs.

Best Practices: Assembly, Use, and Maintenance

-

Assembly: Carefully select the joint size and connection for reservoir, tubing, and discharge jet. LDPE squeeze assemblies minimize human error during rapid fills.

-

Operation: Check the burette brush and dust cover before use. Attach buret to IV pole infusion sack or titration work station with secure joint clip. Use the color-coded gauge and magnetic stirrer if precision mixing is critical.

-

Chemical Compatibility: Always check the pH range, consult compatibility charts for chemicals, and select PTFE or coated components for aggressive solutions.

-

Field Analysis/Industrial Applications: Burettes—especially those with automatic zero point extraction—appear in water treatment plants, industrial chromatography, and field kits with RNA/DNA prep and environmental sample workflows.

-

Quality Control: Select models with NIST-Traceable Calibration, document Order Quantity, Price / Pack, and Quantity / Pack, and ensure compliance with laboratory or BIO Business Solutions inventory systems.

In Summary

Today’s laboratory titration work benefits from self-zeroing burettes constructed from borosilicate 3.3 glass and supported by closed system automation. With features like blue ring graduations, Schellbach stripes, PTFE stopcocks, and flexible LDPE reservoirs, these burettes maximize readability, chemical compatibility, and user safety. Compliance with Class A/B, ASTM E287, and ISO 385 standards, in combination with robust maintenance and sustainability practices, guarantees accurate, reliable volumetric analysis for every analytical chemistry workflow—from field to advanced laboratory research.