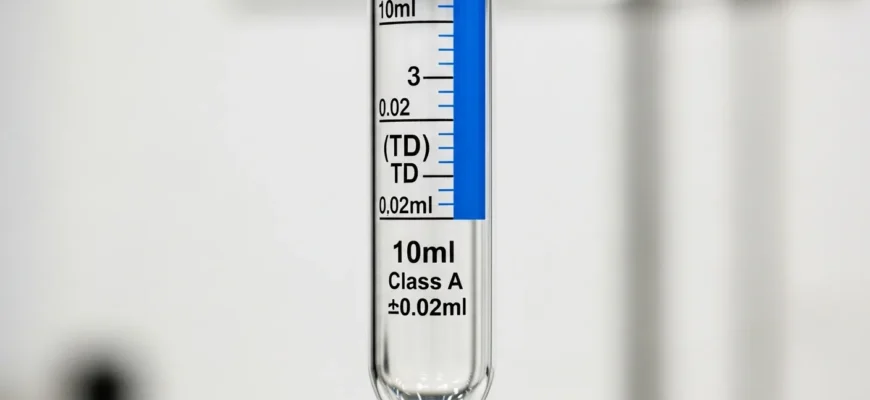

The 10ml Burette: Precision for Small-Volume Titration

In analytical chemistry laboratories, precision becomes exponentially more critical as volumes decrease. When working with samples requiring measurements in the 1-10ml range, a standard 25ml or 50ml burette simply cannot provide the resolution and accuracy demanded by microchemistry applications. The 10ml burette emerges as the essential precision instrument for these specialized tasks, offering significantly enhanced accuracy and finer graduations that make it indispensable for high-precision small-volume titrations.

What makes a 10ml burette different

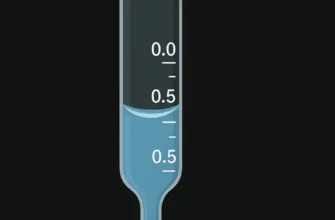

The defining characteristic of a 10ml burette lies in its superior precision capabilities compared to larger volumetric instruments. While standard 25ml burettes typically feature 0.1ml graduations, 10ml burettes provide much finer divisions of 0.05ml or even 0.02ml in high-precision models. This enhanced graduation density allows for readings that are 2-5 times more precise than their larger counterparts.

The tolerance specifications for Class A 10ml burettes are remarkably tight, typically ±0.02ml to ±0.03ml. To put this in perspective, this represents a relative error of just 0.2-0.3% when using the full capacity, compared to 0.1% for a 50ml burette at full volume. However, when working with smaller volumes typical in microchemistry (2-5ml), the 10ml burette maintains superior relative accuracy.

Construction materials play a crucial role in achieving this precision. Borosilicate glass 3.3 serves as the standard material for high-quality 10ml burettes, providing excellent chemical resistance and minimal thermal expansion. The thermal properties are particularly important – with a strain point of 515°C, annealing point of 565°C, and softening point of 820°C, these burettes maintain dimensional stability across typical laboratory temperature variations.

Key features to look for

Stopcock Type: PTFE vs Glass

The choice of stopcock material significantly impacts both durability and performance. PTFE (polytetrafluoroethylene) stopcocks represent the superior option for most applications. Unlike glass stopcocks, PTFE versions offer several advantages:

-

No lubrication required – Glass stopcocks need regular lubrication to prevent freezing, which can contaminate samples

-

Superior chemical resistance – PTFE withstands highly corrosive chemicals that might attack glass

-

Consistent operation – No risk of the stopcock seizing due to chemical reactions or temperature changes

-

Easier maintenance – Simple O-ring seal mechanism rather than ground glass joints

Calibration Class: Understanding Class A Precision

Class A calibration represents the highest precision standard for volumetric glassware, governed by ISO 385 and ASTM E-1189 standards. For 10ml burettes, Class A specification means:

-

Individual calibration and certification of each instrument

-

Tolerance of ±0.02ml to ±0.03ml depending on manufacturer

-

Traceability to national measurement standards

-

Batch certificates documenting actual measured performance

Class A is essential when analytical results demand the highest accuracy, particularly in pharmaceutical analysis, environmental testing, or research applications where precision directly impacts data quality.

Scale Clarity: The Schellbach Stripe Advantage

Schellbach stripe technology revolutionizes meniscus reading accuracy. This feature consists of a vertical white strip with a central blue ribbon positioned opposite the graduation marks. When viewed through a colorless liquid, the meniscus creates an optical effect where “the blue line looks like a double spike”, making the exact liquid level unmistakably clear.

The Schellbach stripe eliminates parallax errors – the reading mistakes that occur when the observer’s eye is not perfectly aligned with the meniscus. This is particularly crucial for 10ml burettes where the fine graduations demand precise reading to achieve the instrument’s full accuracy potential.

Glass vs. digital: Choosing the right type for your lab

Traditional Glass Burettes

Glass burettes remain the standard for most educational and routine analytical applications. Their advantages include:

-

Cost-effectiveness – Significantly less expensive than digital alternatives

-

Fundamental technique development – Teaches proper volumetric measurement skills

-

Reliability – No electronic components to malfunction or require calibration

-

Chemical compatibility – Borosilicate glass withstands most laboratory chemicals

Traditional 10ml glass burettes excel in teaching environments where understanding volumetric principles is essential, and in laboratories where budget constraints make digital instruments impractical.

Digital/Electronic Burettes

Digital burettes represent advanced instrumentation designed for high-throughput and precision-critical applications. Key advantages include:

-

Motorized precision – Eliminates manual speed variations that introduce errors

-

Multiple dispensing speeds – Including dropwise control for endpoint approach

-

Digital readouts – Eliminates parallax and reading errors entirely

-

Data logging capability – Direct connection to laboratory information systems

-

Automated titrations – Programmable dispensing sequences

The accuracy improvement is substantial – electronic burettes achieve precision levels that exceed even Class A glass instruments. However, this performance comes at significantly higher cost and requires regular electronic calibration.

Digital systems prove most valuable in pharmaceutical quality control, environmental monitoring, and research applications where titration throughput is high and result precision directly impacts product quality or regulatory compliance.

A quick buyer’s checklist

When selecting a 10ml burette, consider these decision points:

Application Requirements:

-

Routine analytical work → Class A glass with PTFE stopcock

-

High-precision research → Digital/electronic with data logging

-

Educational use → Standard glass for technique development

-

Corrosive chemicals → PTFE components essential

Budget Considerations:

-

Glass burettes: $100-300 range for quality instruments

-

Digital burettes: $2,000-5,000+ for advanced features

-

Cost justification through time savings and reduced repeat analyses

Durability and Maintenance:

-

PTFE stopcocks eliminate lubrication and freezing issues

-

Borosilicate glass provides chemical resistance and thermal stability

-

Consider replacement part availability and service support

Compliance Requirements:

-

ISO 385 compliance for international acceptance

-

ASTM E-1189 for US laboratory standards

-

Individual certificates for regulated industries

-

Calibration frequency requirements (typically 3-6 months)

Conclusion

The 10ml burette serves as a specialized precision instrument that solves the critical problem of accurate small-volume measurement in analytical chemistry. Its enhanced graduation density, superior tolerance specifications, and advanced features like Schellbach stripes make it indispensable for applications where standard burettes lack sufficient precision.

The optimal choice balances precision requirements with practical considerations including workflow efficiency, budget constraints, and maintenance capabilities. Whether selecting traditional glass for fundamental analytical work or advanced digital systems for high-throughput precision applications, the 10ml burette represents a strategic investment in measurement accuracy.

For any laboratory where precision in the 1-10ml range directly impacts result quality – from pharmaceutical analysis to environmental monitoring to advanced research – the 10ml burette transforms potentially imprecise measurements into reliable, reproducible analytical data. The enhanced accuracy and resolution it provides often prove essential for meeting modern analytical demands where precision cannot be compromised.