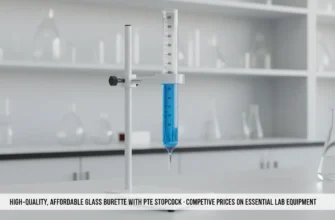

Understanding the Class A Burette: Features and Benefits

Key Highlights

Class A burettes meet the highest standards for precision, ensuring measurements with tolerances as low as ±0.03 mL for a 25 mL capacity. Constructed from high-quality borosilicate glass, this laboratory glassware offers durability and resistance to thermal shock up to 820°C softening point. Features like a PTFE stopcock provide excellent chemical resistance, self-lubrication, and smooth, leak-proof flow control without grease contamination. These burettes conform to DIN EN ISO 385 and ASTM E287 specifications for volumetric accuracy. Individual certification and serialization ensure complete traceability, often linked to NIST standards for measurement reliability. Clear, permanent graduations in high-contrast colors facilitate error-free volume readings by reducing parallax errors.

Introduction

When experiments require the highest accuracy, a Class A burette stands out as essential volumetric glassware for titration and analytical chemistry. It delivers exact volumes with minimal error, making it ideal for reproducible results in professional labs. Understanding its features and benefits builds confidence in laboratory workflows.

What Defines a Class A Burette

The “Class A” label indicates superior precision with the tightest tolerances compared to other glassware classes. It adheres to standards like ASTM E287, ensuring volumes dispensed closely match the graduations. For quantitative analysis, this precision is essential to avoid errors in results.

Key Manufacturing Standards and Certification

Class A burettes follow strict guidelines in ASTM E287 and DIN EN ISO 385 for tolerances, mark dimensions, and delivery times. Reputable manufacturers provide a certificate verifying compliance, often with NIST traceability. NIST defines traceability as relating measurements to standards through an unbroken chain with stated uncertainties. This calibration chain supports regulatory compliance and defensible data in quality-controlled environments.

Differences Between Class A and Class B Burettes

Class A burettes offer tighter accuracy than Class B, crucial for high-precision work. A 25 mL Class A burette has a tolerance of ±0.03 mL, while Class B is ±0.06 mL. Class A markings are finer and more permanent for precise readings. Class B suits general or educational use, while Class A is standard for research and clinical labs.

| Feature | Class A Burette | Class B Burette |

|---|---|---|

| Tolerance (25 mL) | ±0.03 mL | ±0.06 mL |

| Primary Use | Quantitative analysis, research | General lab, education |

| Certification | Individual or batch | Typically none |

| Markings | Permanent, high-contrast | Standard, less detailed |

Main Features of Class A Burettes

Class A burettes prioritize precision and durability for regular use. They feature heavy-duty construction with high-contrast graduations for clear meniscus reading. Modern designs include borosilicate glass and PTFE components for enhanced functionality.

Precision Graduations and Colored Scale Advantages

Graduations are finely etched and permanent, resisting chemical wear. Colored scales, like white or blue enamel, provide high contrast to minimize parallax errors. Benefits include reduced eye strain, improved accuracy, faster readings, and sharper meniscus visibility with Schellbach stripes.

-

Reduced eye strain from high-contrast colors.

-

Minimized misreading risks for better accuracy.

-

Quicker volume determination.

-

Enhanced meniscus clarity.

Material Choices

Borosilicate glass is the preferred material for its chemical corrosion resistance and thermal shock tolerance. It handles rapid temperature changes without cracking, ideal for lab washing or reactions. Alternatives include:

-

Borosilicate 3.3: Low expansion, high resistance standard.

-

Acrylic/plastic: Shatter-resistant for education or field use.

-

Automatic burettes: Hybrid materials for mechanisms.

Benefits of Serialized and Certified Class A Burettes

Serialization etches a unique number linking to batch certificates for traceability. This supports GLP in pharmaceuticals or testing by verifying accuracy. It ensures data integrity if measurements are audited.

Enhanced Accuracy for Titration and Analytical Procedures

Class A burettes are recommended for titrations relying on precise titrant volumes to detect endpoints. Tight tolerances minimize errors in acid-base, redox, or potentiometric methods. Benefits include repeatable results, accurate concentrations, reduced reagent waste, and compliance with standards.

Importance of Calibration, Serialization, and Brand Reputation

Not all Class A burettes are serialized, so select those with NIST-traceable certificates. Brands like Pyrex, Kimble, and Eisco provide reliable calibration. This upholds GLP and ensures long-term performance.

Advanced Components: PTFE Stopcocks and Leak-Proof Performance

PTFE stopcocks offer non-reactive, durable seals without lubrication. Precision-machined for smooth flow control, they prevent leaks and ensure drop-by-drop dispensing.

How PTFE Stopcocks Improve Reliability

PTFE eliminates grease-related contamination and seizing common in glass stopcocks. It resists acids, bases, and solvents, providing inert, smooth operation. This enables fine flow control near endpoints for efficient titrations.

Cleaning and Maintenance Best Practices

Rinse with distilled water post-use; use cleaners for residues. Check for air bubbles by flushing liquid through the tip before filling. Best practices:

-

Rinse with titrant before experiments.

-

Disassemble PTFE stopcock periodically for cleaning.

-

Avoid abrasives to protect glass and markings.

-

Store vertically in clamps or covers to prevent damage.

Conclusion

Class A burettes excel in precision and reliability for chemistry labs through superior materials, standards compliance, and components like PTFE stopcocks. Prioritizing calibration and maintenance ensures accurate titrations and longevity. For university labs, Pyrex and Kimble offer borosilicate construction, clear markings, and PTFE stopcocks for robust performance.

Frequently Asked Questions

Can Class A burettes be used for any chemistry titration?

Yes, their accuracy suits acid-base, redox, or complexometric titrations for reliable endpoints and concentrations.

How do I clean and store a Class A burette to preserve accuracy?

Rinse with distilled water after use, flush for bubbles before titrations, and store vertically clean.

Are Class A burettes always certified and serialized?

Most quality ones are, with NIST-traceable certificates; verify product details for compliance.