Discover the Best E Burette Models for Precision

Key Highlights

Electronic burettes (e-burettes) represent state-of-the-art motor-operated instruments that eliminate human error through automated, controlled piston movement. These sophisticated devices feature touchscreen interfaces with graphical user interfaces (GUI) and three calibrated pre-set dispensing speeds for highly accurate titrations. Motor-controlled operation ensures consistent results by eliminating the variability associated with manual wheel operation found in standard digital burettes. Advanced recirculation systems prevent reagent loss during priming while maintaining bubble-free dispensing. Superior chemical compatibility through materials like borosilicate glass, PTFE, FEP, and ECTFE ensures reliable performance across diverse laboratory applications.

Introduction

Precision liquid handling remains crucial for achieving accurate and reproducible results in modern analytical laboratories. While traditional manual burettes have served as foundational tools, they introduce variables that can compromise data quality through human error and inconsistent operation. Electronic burettes (e-burettes) address these limitations by transforming the titration process through sophisticated automation, enhanced safety features, and unparalleled accuracy. These advanced instruments represent a significant evolution from both glass and digital burettes, offering motor-controlled precision that eliminates operator-dependent variables while delivering superior performance in demanding laboratory environments.

Understanding E-Burettes and Their Role in Modern Laboratories

An electronic burette represents the most advanced form of automated liquid dispensing instrument, utilizing motor-controlled piston movement to provide highly accurate measurements for titration applications. Unlike manual counterparts, e-burettes employ sophisticated motors to control liquid flow, ensuring steady and precise dispensing that eliminates human variability. This technology proves transformative in pharmaceuticals, environmental monitoring, and food analysis where precision directly impacts results quality.

The primary role of e-burettes in analytical chemistry involves automating the dispensing process to minimize human error while guaranteeing consistency across multiple measurements. Their ergonomic design and intuitive operation make them valuable tools for achieving precise results in demanding laboratory conditions. Advanced e-burettes can dispense volumes ranging from 0.01 mL to 99.99 mL with exceptional precision.

What Sets E-Burettes Apart from Traditional Glass and Digital Models

The most significant advantage of e-burettes over traditional glass burettes lies in complete elimination of manual operation. Glass burettes depend on operator control of stopcocks and meniscus readings, leading to inconsistent drop sizes and parallax errors. E-burettes automate this process through motor control, ensuring every titration maintains identical precision levels.

Compared to basic digital burettes using manually operated wheels, advanced e-burettes offer motor-controlled piston movement as a key differentiating feature. This motor control guarantees smoother, more reliable dispensing processes free from abrupt changes occurring with hand-driven mechanisms. The result delivers consistently accurate titrations with superior reproducibility.

E-burettes incorporate sophisticated control panels featuring touchscreen interfaces that allow programming of specific volumes, result storage, and effortless switching between dispensing speeds. This level of control and convenience remains unavailable with traditional models, representing a fundamental advancement in laboratory instrumentation.

Typical Volume Capacities and Dispensing Range

E-burettes are manufactured in standard capacities designed to accommodate different analytical requirements. The capacity selection depends on typical solution volumes used in specific titration applications, with each size optimized for particular precision levels.

The most common e-burette capacities include 10 mL, 25 mL, and 50 mL models. Smaller capacities enable higher precision with finer increments for micro-titrations, while larger volumes suit general-purpose laboratory applications. Digital displays provide clear readings to the third decimal place for enhanced accuracy.

Here are the verified specifications for leading e-burette models based on current industry standards:

Key Advantages of Using E-Burettes for Liquid Dispensing

E-burettes deliver significant benefits that enhance laboratory productivity and data quality beyond traditional methods. The primary advantage involves superior accuracy achieved through automated dispensing processes, ensuring consistent results fundamental for reliable research and quality control. These instruments streamline analytical workflows by reducing physical strain and mental focus required for manual titrations.

Enhanced Accuracy and Precision in Titration Procedures

Motor-driven piston systems achieve the highest accuracy levels in analytical chemistry by delivering continuous, pulse-free liquid flow. This eliminates variability from manual stopcock control, a common error source in traditional titrations. The motorized function ensures dispensing speed remains constant whether filling rapidly or adding liquid drop-by-drop near endpoints.

E-burettes achieve Class A accuracy specifications according to DIN EN ISO 8655 standards. High-quality models provide accuracy within ±0.05-0.10% tolerances with precision to three decimal places. Control panels allow selection of pre-calibrated speeds including very slow dropwise dispensing (0.010 mL/sec) for final titration stages.

This precise control ensures results remain uninfluenced by inconsistent manual operation, making data more reliable and reproducible across multiple operators. The motor-controlled system eliminates human error while maintaining consistent performance throughout extended use periods.

User Convenience and Workflow Improvements in Chemistry Labs

Beyond accuracy improvements, e-burettes prioritize user convenience through intuitive design and ergonomic features that streamline laboratory workflows. Easy-to-use control panels enable complex functions like auto-refilling and zeroing with simple touch operations. Modern e-burettes incorporate features that reduce reagent waste, minimize setup time, and create more comfortable user experiences.

Key convenience features enhancing laboratory efficiency include:

Recirculation Mode: Purges air bubbles without wasting reagents by returning them to the mounted bottle

FlexiNozzle®: Adjustable delivery nozzle offering flexibility in both horizontal and vertical directions for easy dispensing into various vessels

Quick Set Feature: Automatically dispenses previously saved volumes, accelerating repetitive tasks

Touch Screen Operation: Intuitive graphical interfaces guide users through titration processes with minimal training

Innovative Features of Top E-Burette Models

Leading e-burette models incorporate sophisticated features extending far beyond simple dispensing capabilities. The control systems often include full-color graphical user interfaces (GUI) that display data clearly while guiding users through various functions. These advanced systems integrate seamlessly into modern data-driven laboratories through connectivity options and automated functionality.

Motorized Function and Its Impact on Titration Accuracy

State-of-the-art motors form the precision core of e-burette systems, facilitating controlled piston movement that ensures exceptional accuracy. Unlike manual methods relying on operator skill, motors guarantee smooth, pulse-free liquid flow at consistent rates. This technology enables multiple pre-set rotation speeds, allowing fast initial filling followed by precise dropwise dispensing near titration endpoints.

Motor-controlled systems eliminate risk of over-titration from abrupt flow changes associated with manual stopcocks. Precise control guarantees reproducible titrations with results unaffected by operator variability. Three typical dispensing speeds include:

- High Speed: 1.5-3.8 mL/sec for rapid filling

- Medium Speed: 0.5-1.3 mL/sec for controlled dispensing

- Dropwise: 0.010-0.025 mL/sec for endpoint determination

Advanced Connectivity Options for Data Management

Modern e-burettes address digital laboratory requirements through connectivity features like USB ports and RS-232 interfaces. These capabilities allow direct transfer of measurement data from instrument control panels to computers, streamlining record-keeping and supporting Good Laboratory Practice (GLP) compliance.

This connectivity eliminates manual transcription errors while enabling efficient data management for regulatory compliance. Some models store up to 20 results directly in internal memory for quick recall and batch transfer.

Advanced connectivity features include:

USB Connection: Direct data transfer to specialized laboratory software

Portable Printer Integration: Some models connect to portable printers for immediate result documentation with timestamps

Internal Memory: Stores recent results on the device for quick access and batch processing

PC Software Integration: Specialized programs enable advanced data analysis and compliance documentation

Choosing the Best E-Burette Model for Your Laboratory

Selecting appropriate e-burette models requires careful consideration of laboratory-specific requirements including chemical compatibility, volume ranges, and accuracy demands. Important factors include types of reagents used, typical dispensing volumes, and required precision levels for specific analytical work. Consider available accessories like different bottle adapters and light-sensitive reagent protection when evaluating options.

Safety Features to Consider When Purchasing E-Burettes

Safety remains paramount in laboratory equipment selection, with modern e-burettes incorporating systems designed to protect users and maintain experimental integrity. Key safety features extend beyond simple stopcock valves to include comprehensive systems minimizing risk exposure.

Essential safety features include:

Recirculation Mode: Prevents splashing and waste during system purging while reducing chemical exposure

FlexiNozzle®: Flexible delivery system reduces spill risk by directing flow precisely where needed

Closed System Design: Direct bottle mounting minimizes vapor exposure during operation

Sturdy Construction: Stable design prevents tipping and accidental spills during use

Automatic Safety Discharge: Advanced models include safety systems preventing accidental dispensing

Chemical Compatibility with Common Reagents and Laboratory Setups

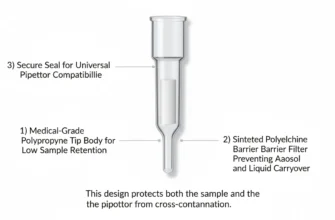

High-quality e-burettes utilize materials selected for excellent resistance to wide ranges of chemicals, ensuring durability and accuracy under various laboratory conditions. Components contacting liquids typically consist of materials like borosilicate glass, PFA, FEP, and PTFE—providing high chemical resistance against most acids, bases, and solvents used in titrations.

The wetted parts of premium e-burettes demonstrate compatibility with most standard laboratory chemicals through careful material selection. Borosilicate glass cylinders, PTFE seals, and ECTFE valve components ensure broad chemical compatibility. However, extremely aggressive chemicals like hydrofluoric acid may require special consideration.

Material specifications for chemical compatibility:

- Cylinder: Borosilicate glass 3.3 for thermal and chemical resistance

- Piston and Seals: PTFE, FEP, or ECTFE for broad chemical compatibility

- Valve Components: PTFE or ceramic materials for corrosion resistance

- Tubing: FEP or PFA for chemical inertness

Practical Guide: Setting Up and Using E-Burettes for Titration

Proper e-burette setup ensures optimal performance and accurate results in practical laboratory environments. The setup process involves systematic mounting, priming, and calibration procedures designed to eliminate air bubbles and ensure precise dispensing. Following manufacturer protocols guarantees instrument readiness for reliable liquid dispensing applications.

Step-by-Step Setup Instructions for Accurate Liquid Dispensing

Systematic setup procedures ensure e-burettes deliver consistent, accurate measurements from initial installation. Proper mounting and priming eliminate common sources of error while establishing optimal operating conditions. The process requires attention to detail but follows straightforward protocols suitable for routine laboratory use.

Complete Setup Procedure:

- Mount the E-Burette: Select appropriate adapter for reagent bottle and securely attach the instrument using proper threading

- Insert Telescoping Tube: Adjust filling tube length to accommodate bottle height without touching the bottom

- Power On and Initialize: Activate the instrument and allow initialization of electronic systems

- Prime Using Recirculation Mode: Engage recirculation to purge air bubbles without reagent waste, returning liquid to the bottle

- Verify Bubble-Free Operation: Ensure complete air removal from cylinder and dispensing lines

- Perform Function Check: Execute test dispensing to confirm proper operation before beginning titrations

Calibration, Maintenance, and Cost Considerations

Regular calibration and maintenance ensure consistent e-burette performance according to laboratory quality standards. Many e-burettes support in-laboratory calibration without specialized tools, enabling compliance with institutional protocols. Understanding total cost of ownership includes initial purchase, maintenance requirements, and operational efficiencies gained through improved accuracy and reduced reagent waste.

E-burette prices vary significantly based on features and capabilities, with basic models starting around $1,000 and premium units exceeding $2,500. However, long-term cost benefits include reduced reagent waste, improved efficiency, and enhanced data quality.

Maintenance Guidelines:

- Regular Calibration: Follow manufacturer recommendations or laboratory protocols for periodic verification

- Cleaning Procedures: Rinse with distilled water between reagents and follow proper cleaning protocols for different chemicals

- Component Inspection: Check seals, pistons, and electronic components for wear or damage

- Proper Storage: Store upright in clean, dry environments to preserve component integrity

Frequently Asked Questions

How do digital burettes compare to e-burettes in terms of laboratory features?

E-burettes represent advanced digital burettes with sophisticated automation features. While all digital burettes display measurements electronically, e-burettes specifically include motor-driven pistons, touchscreen control panels, and pre-set dispensing speeds designed to enhance precision and automation. The motor control eliminates manual wheel operation variability found in basic digital burettes.

What is the average price range for purchasing a high-quality e-burette?

High-quality e-burettes typically range from $1,000 to $2,500 depending on features and specifications. Basic motorized models with touchscreen interfaces start around $1,000, while premium units with full automation, PC connectivity, and printer integration can exceed $2,500. Models with advanced features like recirculation systems and multiple connectivity options command higher prices.

Are e-burettes compatible with all standard laboratory chemicals?

E-burettes demonstrate excellent chemical compatibility through careful material selection including borosilicate glass, PTFE, FEP, and ECTFE components. They handle most standard laboratory chemicals including acids, bases, and organic solvents effectively. However, extremely aggressive chemicals like hydrofluoric acid may require special consideration or alternative equipment. Manufacturers typically provide detailed chemical compatibility charts for specific reagent applications.