Understanding the Uses of Well Plates in Laboratory Settings: A Comprehensive Guide

Key Highlights

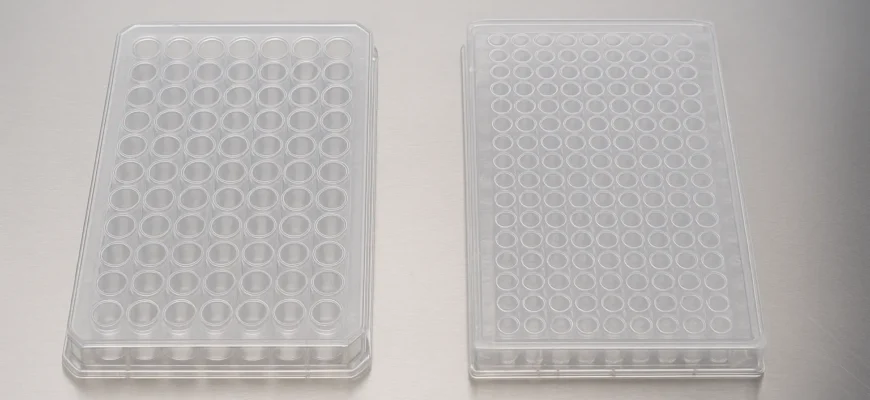

Well plates, also known as microplates or microtiter plates, are essential laboratory tools used extensively in life sciences for applications ranging from cell culture to analytical research. They are manufactured from various materials including polystyrene, polypropylene, and glass, with each material suited for specific applications based on chemical resistance, optical properties, and temperature stability.

The most common formats include 6, 24, 96, 384, and 1536-well plates, with higher density formats like 3456 and 9600-well plates available for specialized applications. The 96-well format remains the most widely used due to its compatibility with both manual handling and automated systems.

Standardization by the American National Standards Institute (ANSI) and the Society for Laboratory Automation and Screening (SLAS) ensures compatibility with laboratory automation systems and plate readers through five key standards covering footprint dimensions, height, flange dimensions, well positions, and well bottom elevation.

Introduction

In modern laboratory settings, well plates represent one of the most fundamental pieces of equipment for high-throughput analysis and research. These multi-well platforms enable scientists to conduct hundreds or thousands of experiments simultaneously, revolutionizing how research is conducted across disciplines from drug discovery to clinical diagnostics.

The versatility of well plates extends far beyond simple sample storage. They serve as the foundation for enzyme-linked immunosorbent assays (ELISA), cell culture experiments, high-throughput screening, and numerous other applications that form the backbone of contemporary biological and chemical research.

What is a Well Plate?

A well plate is a flat, rigid plate containing multiple small wells arranged in a standardized rectangular grid pattern. Each well functions as an individual test tube, allowing researchers to process multiple samples simultaneously while maintaining sample integrity and reducing contamination risks.

These plates are also commonly referred to as microplates or microtiter plates, terms that are used interchangeably in laboratory settings. The “microtiter” designation, originally a trademark, has become a generic term much like “Kleenex” for tissues.

The primary advantage of well plates lies in their ability to enable high-throughput processing. A single 96-well plate can accommodate 96 individual experiments, while 384-well plates can handle 384 samples, dramatically increasing experimental efficiency and reducing reagent consumption.

Structure and Design Standards

ANSI/SLAS Standards

Well plate standardization is maintained by the Society for Laboratory Automation and Screening (SLAS) in collaboration with the American National Standards Institute (ANSI). These standards, established in 2004 and reaffirmed in 2017, include five key specifications:

-

ANSI/SLAS 1-2004: Footprint Dimensions (127.76 mm × 85.48 mm)

-

ANSI/SLAS 2-2004: Height Dimensions

-

ANSI/SLAS 3-2004: Bottom Outside Flange Dimensions

-

ANSI/SLAS 4-2004: Well Positions

-

ANSI/SLAS 6-2012: Well Bottom Elevation

Physical Design Elements

The standard design features a rectangular footprint with wells arranged in a grid pattern. For 96-well plates, wells are spaced 9 mm apart center-to-center, allowing for precise automated handling. Well shapes vary based on application needs, including flat-bottom (F-bottom), round-bottom (U-bottom), and V-bottom configurations.

Deep well plates represent a specialized variant that maintains the standard footprint while providing significantly increased well depth and volume capacity (up to 2 mL per well), making them ideal for sample storage and preparation.

Materials and Manufacturing

Common Materials

Polystyrene (PS) is the most prevalent material for well plates, offering excellent optical clarity for absorbance and colorimetric assays. It’s available in clear, black, and white variants, with each color optimized for specific detection methods.

Polypropylene (PP) provides superior chemical resistance and temperature stability, making it suitable for applications involving organic solvents or temperature cycling. Unlike polystyrene plates, polypropylene plates can be autoclaved for sterilization and reuse.

Glass and Quartz materials offer the highest optical transparency and chemical resistance but are more expensive and fragile. They’re primarily used for specialized applications requiring extreme solvent resistance.

Manufacturing Process

Well plates are primarily manufactured using injection molding processes, which allow for precise control over well dimensions, wall thickness, and surface properties. This method ensures consistency across batches and compatibility with automated systems.

Surface Treatments for Cell Culture

Tissue Culture Treatment

For cell culture applications, well plates often undergo tissue culture (TC) treatment, a plasma-based surface modification process. This treatment converts the naturally hydrophobic plastic surface to a hydrophilic, cell-adhesive surface through controlled plasma exposure.

The plasma treatment introduces oxygen-containing functional groups onto the surface, improving protein adsorption and cell attachment while maintaining surface sterility. This modification is essential for culturing adherent cells, which require a suitable surface for attachment and growth.

Specialized Coatings

Additional coating options include:

-

Poly-D-Lysine and Poly-L-Lysine: Enhance cell attachment for difficult-to-culture cells

-

Glass coating: 200nm silicone dioxide layer providing glass-like properties while maintaining plastic advantages

-

High-binding surfaces: Modified for enhanced protein adsorption in ELISA applications

Well Plate Formats and Specifications

| Format | Wells | Typical Volume | Well Spacing | Common Applications |

|---|---|---|---|---|

| 6-well | 6 | 2-5 mL | 39.12 mm | Large-scale cell culture |

| 24-well | 24 | 0.5-3 mL | 19.30 mm | Medium-scale cultures, assays |

| 96-well | 96 | 100-360 µL | 9.00 mm | ELISA, high-throughput screening |

| 384-well | 384 | 35-112 µL | 4.50 mm | Miniaturized assays, drug screening |

| 1536-well | 1536 | 8-15 µL | 2.25 mm | Ultra-high throughput screening |

Sterilization and Reusability

Sterilization Methods

Most plastic well plates are designed for single-use to prevent cross-contamination, particularly in sensitive applications like cell culture. However, sterilization options vary by material:

Polypropylene plates can be sterilized by autoclaving at 121-134°C, making them suitable for reuse in appropriate applications. The material’s thermal stability allows it to withstand multiple autoclave cycles without significant degradation.

Glass plates can be thoroughly cleaned and sterilized using various methods including autoclaving, making them cost-effective for repeated use.

Polystyrene plates are generally single-use only due to their lower thermal stability and the risk of deformation during heat sterilization.

Sterility Maintenance

For applications requiring sterile conditions, pre-sterilized plates are available and packaged to maintain sterility until use. These plates undergo gamma irradiation or other validated sterilization processes during manufacturing.

Preventing Edge Effects and Contamination

Edge Effect Phenomenon

Edge effect refers to the increased evaporation rate in perimeter wells compared to central wells, leading to concentration changes and experimental variability. This phenomenon affects all microplate formats but is more pronounced in high-density plates with smaller well volumes.

Prevention Strategies

Moat Design: Specialized plates like the Nunc Edge 2.0 feature perimeter moats that can be filled with sterile water to create a humidity barrier, significantly reducing evaporation in outer wells.

Environmental Controls: Maintaining incubator humidity above 95%, minimizing door openings, and using appropriate plate covers can reduce evaporation.

Sealing Methods: Heat-sealing films for biochemical assays or breathable sterile tapes for cell-based assays provide effective evaporation barriers.

Laboratory Applications

ELISA and Clinical Diagnostics

Well plates are fundamental to enzyme-linked immunosorbent assays (ELISA), which form the basis of most modern clinical diagnostic testing. ELISA applications include detection of infectious agents, measurement of antibody responses, and quantification of biomarkers.

Different ELISA formats require specific plate types:

-

High-binding plates for enhanced antigen/antibody capture

-

Low-binding plates for reduced non-specific binding

-

Specialized coatings for specific biomolecule capture

Cell Culture Applications

Well plates enable scalable cell culture from small-scale screening to larger preparation cultures. The format selection depends on required cell numbers, media volume, and experimental duration. Tissue culture-treated surfaces are essential for adherent cell lines, while low-attachment surfaces benefit suspension cultures.

High-Throughput Screening

In drug discovery, well plates enable screening of thousands of compounds simultaneously. The 384-well and 1536-well formats are particularly valuable for miniaturizing assays and reducing reagent costs while maintaining statistical reliability.

Quality Assurance and Best Practices

Contamination Prevention

Proper aseptic technique is crucial when working with well plates. This includes working in sterile environments, using sterile tips for each transfer, and maintaining plate covers when not in active use. For long-term cultures, preventing evaporation becomes critical for maintaining cell viability and assay reliability.

Plate Selection Criteria

Choosing the appropriate well plate requires considering:

-

Assay type: Optical requirements (clear, black, white)

-

Cell type: Surface treatment needs

-

Volume requirements: Well capacity and working volume

-

Automation compatibility: ANSI/SLAS standard compliance

-

Chemical compatibility: Material resistance to solvents and reagents

Conclusion

Well plates represent a cornerstone technology in modern laboratory research, enabling high-throughput, reproducible experiments across diverse applications from basic research to clinical diagnostics. Understanding their design principles, material properties, and proper application ensures optimal experimental outcomes and data reliability.

The continued evolution of well plate technology, including specialized surface treatments, edge effect mitigation designs, and ultra-high density formats, reflects their central importance in advancing scientific research capabilities. Proper selection and handling of these versatile tools remain critical for maintaining experimental integrity and achieving reliable results in laboratory settings.

Frequently Asked Questions

Are well plates reusable or designed for single-use?

Most polystyrene well plates are designed for single-use to prevent cross-contamination. However, polypropylene and glass plates can often be reused after proper cleaning and sterilization, with polypropylene plates being autoclavable at 121-134°C.

How are microplates and well plates related?

The terms “microplate,” “well plate,” and “microtiter plate” are used interchangeably to describe the same laboratory tool. “Microtiter” was originally a trademark but has become generic terminology, similar to how “Kleenex” is used for tissues.

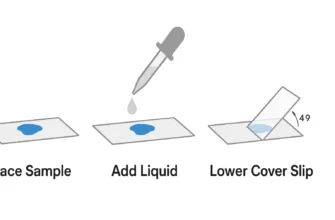

What are tissue culture-treated plates?

Tissue culture-treated plates undergo plasma surface modification to convert the hydrophobic plastic surface into a hydrophilic, cell-adhesive surface. This treatment is essential for culturing adherent cells that require surface attachment for proper growth and function.