Discover the Best 384 Well Plate for Your Experiments: Complete Guide

Key Highlights

384 well plates are essential tools for high-throughput laboratory experiments, offering increased efficiency and reduced reagent consumption. The choice between polypropylene and polystyrene materials significantly impacts experimental outcomes, with polypropylene excelling in thermal stability for PCR applications and polystyrene providing superior optical clarity for cell culture and imaging. Specialized coatings and optically clear bottoms enhance performance for cell culture and imaging assays, with tissue culture (TC) treated surfaces promoting cell adhesion and clear bottom plates enabling high-quality microscopy. PCR plates must be certified free of contaminants like DNase, RNase, and human DNA to ensure reliable amplification. ANSI/SLAS standards ensure compatibility with automation systems, while proper sealing with plates sealers or adhesive films prevents evaporation and contamination. Leading manufacturers like Eppendorf, Corning, USA Scientific, and Greiner Bio-One provide high-quality options for applications ranging from high-throughput screening to sample storage.

Introduction

The 384 well plate has revolutionized modern laboratory workflows by enabling researchers to run four times as many samples as traditional 96-well plates while significantly reducing reagent consumption and costs. These high-density microplates have become indispensable tools in drug discovery, molecular biology, cell culture, and high-throughput screening applications.

Whether performing complex PCR assays, conducting cell-based experiments, or running large-scale screening programs, selecting the appropriate 384 well plate is crucial for achieving accurate and reliable results. The miniaturized format allows for working volumes as small as 5-40 µL while maintaining excellent assay performance.

This comprehensive guide examines the critical factors for selecting optimal 384 well plates, from material properties and surface treatments to brand considerations and application-specific requirements.

Types of 384 Well Plates for Laboratory Applications

384 well plates are available in diverse configurations to meet specific experimental needs. The fundamental distinction lies in the base material, with polypropylene and polystyrene being the primary options, each offering unique advantages for different applications.

Beyond material selection, plates feature various well volumes, surface treatments, and optical properties. Standard 384 well plates typically offer working volumes ranging from 25-145 µL, while low-volume variants accommodate as little as 4-25 µL for reagent-sensitive applications.

Well geometries also vary significantly, with options including flat bottom, round bottom, V-bottom, and conical designs optimized for different sample recovery requirements and assay types.

Polypropylene vs. Polystyrene 384 Well Plates

Polypropylene 384 well plates excel in applications requiring thermal stability and chemical resistance. These plates withstand temperature cycling from -196°C to +121°C without warping, making them ideal for PCR, qPCR, and sample storage applications. The material’s low-binding properties prevent protein and DNA adhesion, ensuring maximum sample recovery.

Polystyrene 384 well plates provide superior optical clarity and are the preferred choice for cell culture and imaging applications. Their natural transparency enables excellent microscopic observation, while specialized surface treatments can be applied to modify cell adhesion properties.

Both materials are manufactured in clean room environments and certified free from common contaminants including DNase, RNase, and human DNA. The choice between materials should align with specific experimental requirements, with polypropylene favored for molecular biology and storage, while polystyrene is optimal for cell-based assays and optical applications.

Coatings, Treatments, and Optically Clear Bottoms for Imaging Assays

Surface treatments are crucial for cell culture applications in 384 well plates. Tissue culture (TC) treated surfaces undergo plasma treatment to create hydrophilic conditions that promote cell attachment and growth. These treatments are essential for adherent cell cultures and maintain stability for extended periods.

Non-binding surfaces are specifically designed for protein and nucleic acid applications where sample recovery is critical. These treated surfaces minimize molecular adhesion, ensuring maximum recovery of valuable samples during quantification assays.

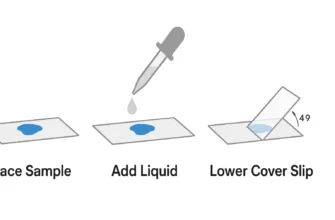

For imaging applications, optically clear bottom plates feature ultra-thin bottoms (typically 190 µm) that provide excellent optical clarity comparable to glass-bottom plates. These plates are engineered for high-content screening, confocal microscopy, and fluorescence imaging with minimal autofluorescence and superior image quality.

Color variations offer specific advantages: white wells enhance fluorescent signal reflection and reduce background luminescence, while black wells minimize crosstalk in luminescent assays and reduce light scattering.

Choosing the Best 384 Well Plate for Your Experiment

Selecting the optimal 384 well plate requires careful consideration of experimental parameters and application requirements. Working volumes typically range from 25-145 µL for standard plates, with specialized low-volume formats accommodating 4-40 µL for reagent-sensitive applications.

Well-to-well spacing in 384 well plates follows the standard 4.5 mm center-to-center distance, ensuring compatibility with multichannel pipettes and automated liquid handling systems. This standardized geometry enables precise sample transfer and reduces the risk of cross-contamination.

Plate dimensions adhere to ANSI/SLAS standards with footprint dimensions of 127.76 mm × 85.48 mm, ensuring compatibility with automated systems, incubators, and plate readers.

PCR Applications, Sample Storage, and Non-Binding Options

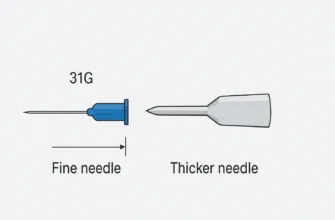

PCR 384 well plates require specific design features for optimal thermal cycling performance. These plates feature ultra-thin walls (typically 0.2 mm) for efficient heat transfer and reduced cycle times. The plates are manufactured from virgin polypropylene and certified free from PCR inhibitors, DNase, RNase, and human DNA.

Skirted designs provide mechanical stability during automated handling and thermal cycling, with options including full-skirted, semi-skirted, and unskirted formats depending on thermal cycler compatibility. White wells are preferred for real-time PCR applications as they enhance fluorescence reflection and improve signal detection.

For sample storage, 384 well plates offer high-density solutions with excellent chemical resistance. Polypropylene construction withstands temperatures from -196°C to +121°C and resists common laboratory solvents including DMSO. Raised well rims enable secure sealing with adhesive films or heat seals to prevent evaporation during long-term storage.

Deep well variants accommodate larger storage volumes up to 200-250 µL while maintaining the standard 384 well footprint, ideal for compound libraries and high-throughput storage applications.

Leading Brands and Essential Features

The 384 well plate market features several established manufacturers known for quality and reliability. Corning offers extensive options including clear, black, and white polystyrene plates with various surface treatments and optical bottom configurations. Their plates meet ANSI/SLAS standards and include specialized high-content imaging plates with ultra-flat bottoms for microscopy applications.

Eppendorf provides innovative designs featuring their twin.tec technology for enhanced thermal transfer and mechanical stability. Their plates include OptiTrack matrix systems for improved sample identification and RecoverMax well geometry for optimal sample recovery.

Greiner Bio-One specializes in both polystyrene and polypropylene variants with options for small volume applications and deep well storage. Their plates feature excellent chemical resistance and are available with various surface treatments.

USA Scientific, Bio-Rad, and Thermo Fisher Scientific round out the leading manufacturers, each offering specialized features for specific applications.

Top Manufacturers and Filter Choices for 384 Plate Selection

When selecting 384 well plates, key filtering criteria include material type (polypropylene vs. polystyrene), well color (clear, white, or black), surface treatment (untreated, TC-treated, or specialized coatings), and sterility (sterile vs. non-sterile).

Volume specifications are critical, with options ranging from low-volume formats (25-50 µL) to standard volumes (112-135 µL) and deep well configurations (200+ µL). Bottom configurations include flat, round, V-shaped, and optically clear variants optimized for specific applications.

Sealing compatibility should be considered, with plates designed for adhesive films, heat seals, or cap mats depending on storage and processing requirements. Automation compatibility through ANSI/SLAS standard compliance ensures proper fit with robotic systems and liquid handlers.

Certification levels vary from basic RNase/DNase-free to specialized PCR-clean grades with comprehensive contamination testing.

Frequently Asked Questions

What is the capacity or volume of a standard 384 well plate?

Standard 384 well plates typically feature maximum well volumes ranging from 50-135 µL, with recommended working volumes of 25-80 µL. Low-volume variants offer maximum capacities of 28-50 µL with working volumes as low as 4-25 µL. Deep well plates can accommodate up to 200-250 µL for storage applications. The reduced volume compared to 96-well plates enables significant reagent savings while maintaining assay performance.

Are there special 384 well plates for imaging or fluorescence assays?

Yes, specialized imaging 384 well plates feature optically clear bottoms with ultra-thin construction (190 µm thickness) for high-resolution microscopy. These plates often include black walls to minimize crosstalk and are designed with flat bottom geometry for consistent focal planes. Many are available with tissue culture treatment for cell-based imaging assays and meet stringent optical quality standards for high-content screening applications.

Can 384 well plates be used effectively for both sample storage and high-throughput screening?

Absolutely. Polypropylene 384 well plates excel at both applications due to their chemical resistance and temperature stability (-196°C to +121°C). For storage, plates feature raised well rims for secure sealing and are compatible with various sealing methods including heat seals and adhesive films. The standardized ANSI/SLAS footprint ensures compatibility with automated liquid handling systems for high-throughput workflows. Deep well variants offer increased storage capacity while maintaining automation compatibility.

Conclusion

Selecting the optimal 384 well plate is fundamental to experimental success across diverse laboratory applications. The choice between polypropylene and polystyrene materials should align with specific requirements: polypropylene for thermal stability in PCR and storage applications, and polystyrene for optical clarity in cell culture and imaging assays.

Surface treatments and specialized coatings significantly impact performance, with TC-treated surfaces essential for cell culture and non-binding surfaces critical for sample recovery. Optically clear bottoms enable high-quality imaging and microscopy applications.

ANSI/SLAS compliance ensures automation compatibility, while proper sealing solutions prevent evaporation and contamination during processing and storage. Leading manufacturers including Corning, Eppendorf, and Greiner Bio-One provide comprehensive options to meet diverse experimental needs.

The investment in high-quality 384 well plates directly impacts experimental reliability and data quality. For guidance in selecting the most appropriate plates for specific applications, consultation with technical specialists can ensure optimal results and cost-effectiveness for laboratory workflows.